Having equipped two Paris hospitals (Corentin-Celton and Vaugirard-Gabriel-Pallez), Burlodge installed another pioneering meal delivery system in the renowned Georges-Pompidou European Hospital. A dynamic fleet of 35, light and highly manoeuvrable meal delivery trolleys ensure that meals are served at the right temperature.

By Marc Ozias

Between breakfast, lunch and dinner, 1,300 meals are served daily in the Georges-Pompidou European Hospital’s rooms, where thirty-five

Trans-Rack trolleys, bearing the Burlodge logo, were recently introduced. The transition took place last summer, during what is normally a calmer period of activity. But within this facility, considered amongst the highest classed in certain specialties (oncology, cardio-vascular surgery and digestive surgery), the pace of work is always very intensive. “One of our main misgivings was the logistics”, admits Thierry Camus, sales director and head of Burlodge France, recollecting the five articulated trucks that delivered the fleet of trolleys to this flagship of the West Paris University Hospital Centre. A team of five people came from the factory to accompany the installation. Fortunately, everything went very well, he was pleased to say. The 700-bed George Pompidou project was the result of a process which began in 2011 by the West Paris University Hospitals.

It united Corentin-Celton (500 beds) and Vaugirard-Gabriel-Pallez (250 beds), respectively equipped with 25 and 16 Burlodge trolleys, in 2011 and 2014.

At the leading edge

At George Pompidou, there came a time when the food service department wanted to improve its equipment. “We no longer wished to make the meals on site, but wanted to have frozen individual single-serve plates delivered”, states Patrick Saulnier, the catering service manager at the George Pompidou. “We therefore needed a new generation of tools to reheat and transport the meals: light and manoeuvrable equipment to replace our old, heavy, obsolete trolleys, which no longer heated adequately. As we had already installed Burlodge meal delivery equipment in Corentin-Celton, we tested them at the Pompidou Hospital”. From the catering service’s desire for change, to the final decision to replace the whole fleet, two years of negotiation with the doctors was required to get a budget allocation of capital funding.

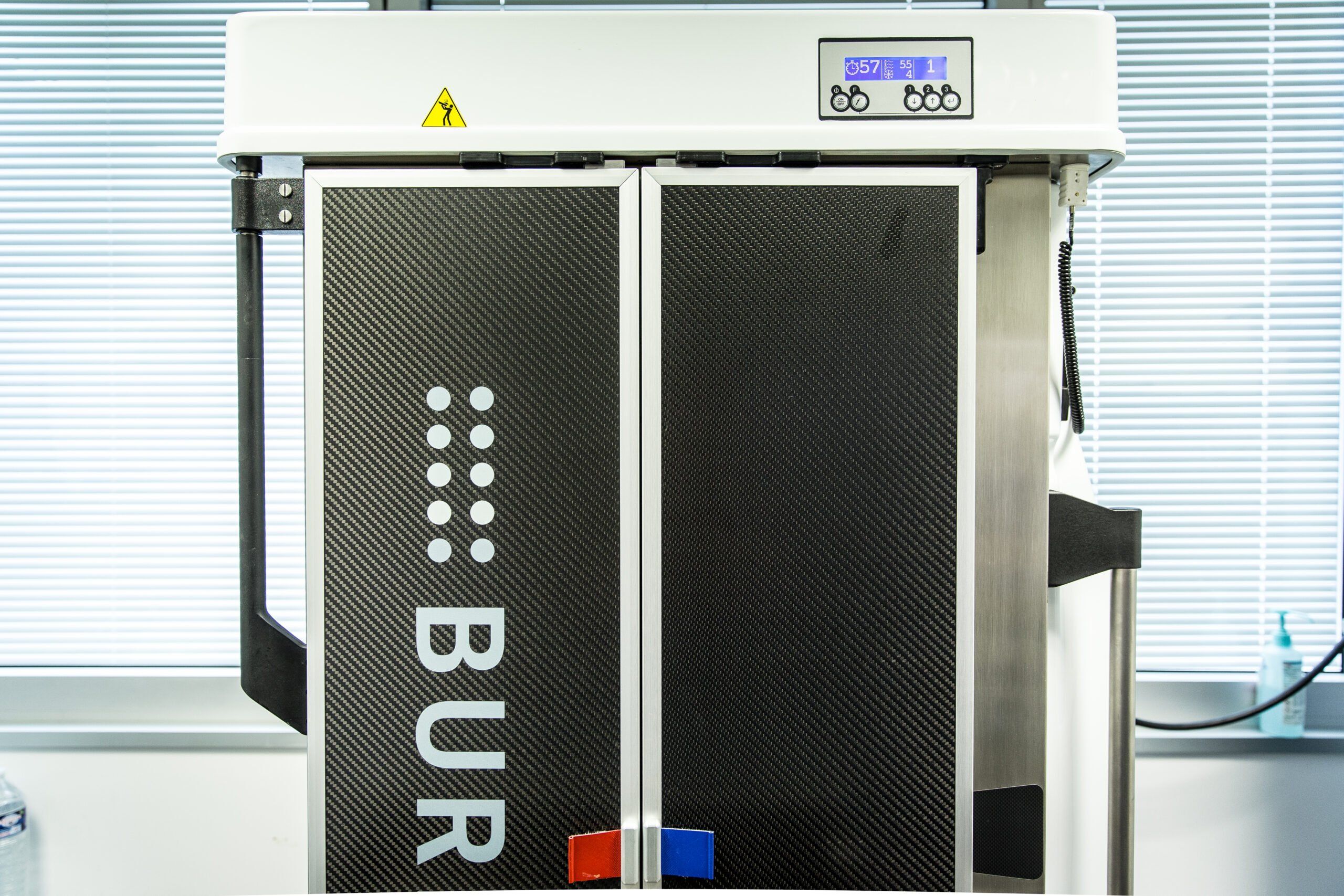

Henceforth, the three establishments have the same model: the ultra-light Trans-Rack, RTS CT (Ready To Serve Carbon Tech), constructed in stainless steel and carbon, equipped with a removable rack weighing about sixty kilos, which is transported on an easy to move dolly around each floor. The stationary part

of the equipment remains in the pantries and therefore does not suffer wear and tear. “Competitor models consist of one single block and weigh nearly 200 kilos. This is why the Burlodge solution is the most interesting”, confirms Patrick Saulnier, who researched four companies for the tender. “We worked with the Health, Safety and Working Conditions Committee, tested the control panel functions, the reheating and temperature maintenance, the handling of the trolleys, as well as the cleaning and maintenance requirements.” The audit did not stop there. It was extended to inspection of the manufacturers’ locations, such as Burlodge’s Italian factory. We found that it is a reliable assembly company, with trolleys made to measure and that the site is clean and well designed. It is reassuring when one sees that elsewhere, everything is done in a haphazard manner.” Once we had completed the overview, the four companies were graded and Burlodge received top marks. Only the adaptation to a robotised equipment transport system “the tortoises”, specific to the hospital, required a modification to the height of the Trans-Rack’s casters and the inner frame of the trolleys. This allowed the equipment to be transported by the famous ‘tortoises’, travelling through all the recesses of the hospital robotically. Thirty-five pantries were fitted with the RTS CT static reheating trolleys.

Choice of hot or cold preparations

During transport, the temperature of the meal trays stays within safe food handling parameters only to meet up with the RTS CT at the pantry where the food trays can be kept cold until the internal programmable clock begins reheating the food that is to be served hot. The RTS CT is divided into two sections, separated by an insulated wall. One is for refrigerating, whereas the other one has its temperature increased to over 130°C, for close to an hour, in order to serve a hot meal to the patient, at the correct food safe service temperatures. “We bring the food to a hot temperature of 70°C to 80°C so we can distribute all the meal trays steadily at the right temperature during tray distribution”, specifies Patrick Saulnier. Being multipurpose, the equipment system can be used for hot or cold preparations. “The Pompidou Hospital, which chose to use solely frozen products, meant that we re-programmed each trolley to support frozen food. Air convection technology allows us this adaptability”, explains Thierry Camus head of Burlodge France.

Light and Ergonomic

Installation of the Trans-Rack was accompanied by a week of training, taken by nearly two hundred hospital employees. Sessions of about 20 minutes were sufficient to ensure that the Burlodge teams explained all the equipment functions, the lightness and manoeuvrability of which was particularly appreciated by the users. “With the previous equipment, staff had to push a 200-kilo trolley, with no visibility. Today, staff work in much more ergonomic conditions. They are happy and say

so. The Health, Safety and Working Conditions Committee have observed fewer musculoskeletal disorders, tendonitis or back pain and, consequently, fewer staff absences due to sickness. Undeniably, it is a sizeable investment, but it is also a real source of savings. Staff are healthier and maintenance costs are reduced”, the head of catering for the West Paris University Hospital states with satisfaction.

In fact, the Georges-Pompidou Hospital inspired the Robert Debré, the largest French paediatric hospital, to invest in Burlodge trolleys too.

The hospital’s clients were involved and participated. They helped us build a partnership relationship, not just a client and supplier one.