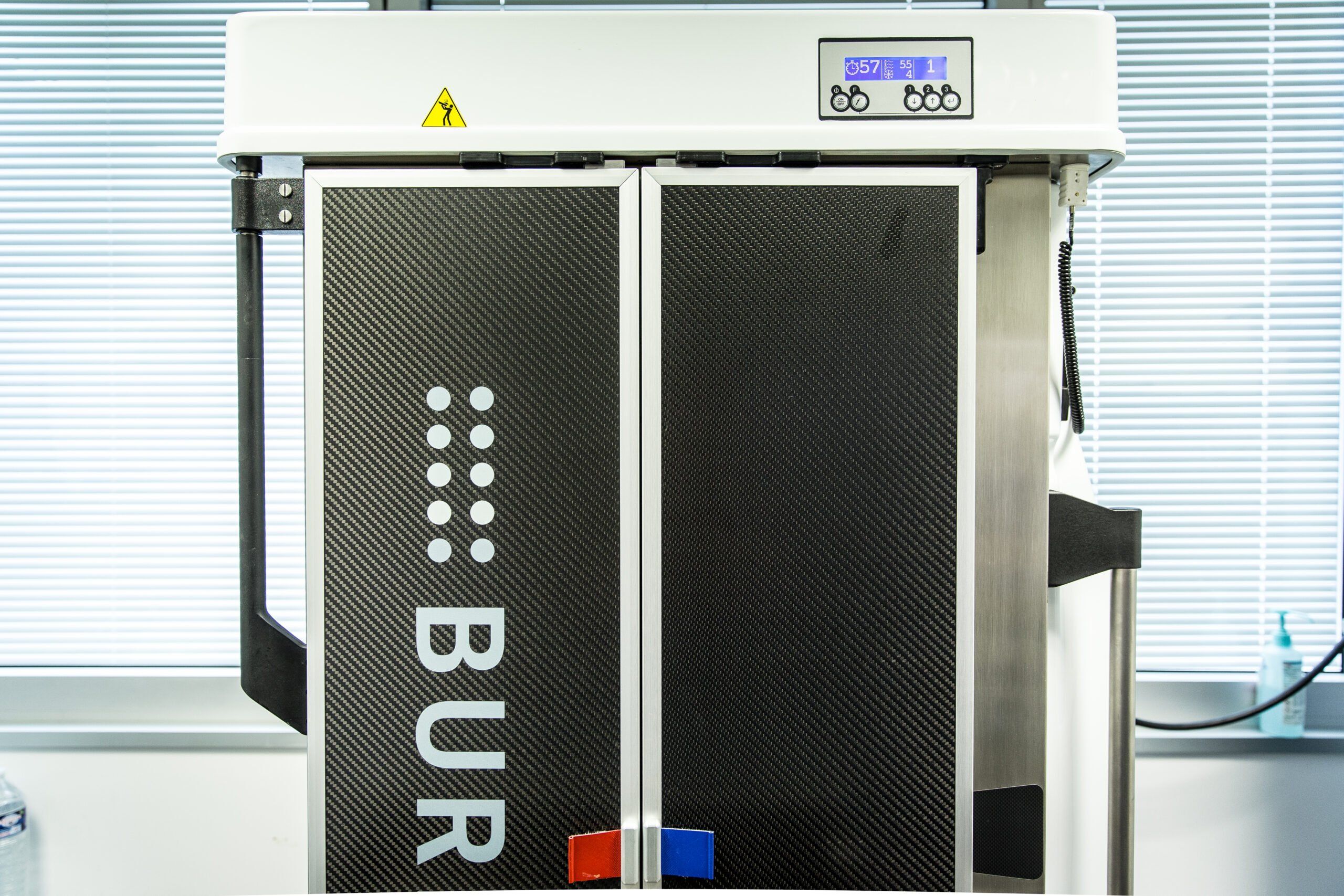

The Orthopaedic Centre in Dracy-Le-Fort, France, is the first French health establishment to use Burlodge’s RTS CT TransRack meal delivery system. This innovative trolley has even been integrated into the central kitchen design, reports Marc Ozias

“The RTS CT TransRack is the ultimate hospital catering tool. It’s a proven concept,” says Pierre-Andre Villard, Burlodge’s regional director in South East France and the French overseas territories. Launched in 2011, this model is better designed to reduce the risk of developing repetitive strain injury. The RTS CT TransRack also improves logistics, distribution and cleaning processes, while enhancing food quality. “These are many critical factors at play today.” explains Villard. “The choice of trolleys for a hospital is decided by a long line of stakeholders.”

“We therefore had to convince the health authorities, the buyers, the unions, the logistics coordinators, domestic services and the users to accept the trolley’s innovation removable transfer rack as a unique solution, where the trays are transported on a TransRack that is separate from the RTS CT trolley.”

Villard, who joined Burlodge from the hospitality industry, could see the benefits of this system and became the first to implement the RTS CT TransRack trolley in France. His first order was for three RTS CT trolleys for the prestigious Orthopaedic Centre in Dracy-Le-Fort, a village of about 1,500 inhabitants between Lyon and Dijon. As this is a hospital treating musculoskeletal disorders, selecting human factor-friendly equipment was of paramount importance. Before making a decision the proposed equipment was heavily scrutinized.

Light and reliable

Burlodge has managed to reduce the weight of its trolleys by 15% with the deign of the RTS CT carbon door. Not only does the equipment weigh less but it is also designed for hotline, cook-chill and cook-freeze applications. “When we started thinking about how we could cut catering costs for the Orthopaedic Centre and the Dracy Santé group, we thought about the possibility of serving meals the neighbouring hospitals. So, with a central kitchen in mind, we approached Burlodge,” explains Mathieu Mercier, manager of Unirest, a subsidiary of Dracy Santé, which oversees the group’s catering services. “We were attracted by Burlodge because they offer reliable equipment that is easy to clean, efficient and conforms to the IP55 European hosing standards. The trolleys weigh much less than other equipment on the market and the removable TransRack concept guaranteed real logistical savings – for example, you only need a simple 3.5 ton vehicle to transport the TransRacks rather than a heavy goods vehicle for trolleys,” says Mercier.

From an ergonomic point of view, it clearly makes a difference. Instead of a 200kg load to transport, it is only 80kg (fully loaded). Lighter and quicker, the RTS CT TransRack is also more manageable. It is easier to handle in the corridors, which helps prevent damage to walls, and is safer for users. “All these improvements persuaded us to continue our partnership with Burlodge,” explains Mercier.

The project started in 2010, with the construction of a new 60-bed hospital wing.

The Local Health Authority recommended that patients in Orthopaedic Centre should be able to choose where they eat their meals. The Burlodge RTS CT TransRack allowed the Centre to serve meals in bedrooms or in the dining room. “We are implementing the system in several stages,” says Mercier, who has built up a wealth of experience in the catering industry.

His experience has helped transform hospital catering. In fact, when it came to creating a new central kitchen, the manager of Unirest wanted to build a structure that could also be used to deliver services to neighboring hospitals, a design based on the use of RTS CT TransRack trolleys from the very beginning.

“Burlodge has managed to reduce the weight of its trolleys by 15% with the design of the RTS CT carbon door… The equipment is designed for hotline, cook-chill and cook-freeze applications“

Significant productivity gains

A 1,071 sq m kitchen with a cafeteria for up to 120 staff and visitors was constructed next to the Orthopaedic Centre in 2014.

The kitchen serves a fleet of 15 RTS CT trolleys. It was designed to minimize transportation

and the meal delivery system operates with 30 TransRacks. It also includes appropriately-sized areas for loading TransRacks, storing clean ones, returning dirty ones, and cleaning them.

“It may seem like a luxury but it has allowed us to optimize the way we work and how we manage staff. While the designers anticipated the need for six operators, we managed to reduce it to three full-time employees (FTEs) without compromising the quality of service,” says Mercier.

“The RTS CT TransRack also has undeniable environmental benefits as it requires less cleaning time, as well as reducing water and detergent consumption,” he says.

The central kitchen produces up to 2,500 meals a day, of which 300 go to the Orthopaedic Centre. The kitchen also delivers plated meals to the Park Centre in Autin and the Red Cross Physio and Rehabilitation Center in Couches, within a 20km radius.

The aim is to provide a regional distribution service and deliver meals to establishments without catering facilities within 40km of the central kitchen. Taking the regulatory five-day use-by date into account, some meals are occasionally delivered as far away as Paris.

However, the trolleys are more appropriate for distances up to 25km. This system becomes less economical over a certain distance, due to the length of the journeys that are necessary in the morning, at lunch and at dinner, as well as the time needed for cleaning the trolleys, washing the trays and reloading fresh meals.

“If the type of meal is not suitable for some schools or businesses, we can always find new outlets, for example, catering services, where there is increasing demand.

Our aim is to standardize production,” says Mercier. “The Burlodge trolleys help us to adapt our services for large events serving 180-200 meals. We do this by plating up in the kitchen and programming the machine to keep the meals cold, then regenerating them before service. We are really competitive with this type of service.”

The air-convection regeneration principle used in the trolley, that guarantees the quality of the regenerated food, is another significant advantage of this product. “We can even make really crispy chips,” he adds.

Experience and evolution

As a faithful user of Burlodge trolleys, Mercier is a fount of knowledge for Burlodge’s R&D department. “I was the first customer to use the RTS CT and I have taken part in numerous trials with the manufacturer. I know these machines very well now.”

Using his background and experience, Mercier had a radio probe installed inside the trolleys to remotely monitor the reheating process. The data is transmitted over Wi-Fi, then is collected by

in-house software together with data from fridges, ovens and blast-chillers. The catering service has even integrated an infrared cell inside the trolleys to detect the insertion of the TransRack. “The refrigeration starts at this point, which prevents misuse,” says Mercier.

Carried out in accordance with Burlodge’s regional director, these modifications have not affected the trolley warranty – a sign of mutual trust. Some of the improvements were tested on site at Dracy-Le-Fort while others were tested by the manufacturer.

“The experts at Burlodge are open to improving the equipment as well as taking a strategic approach to designing the trolleys,” Mercier says.

In his opinion, the success of this partnership comes from a good working relationship, backed up by a high-level maintenance contract that guarantees high-quality meals and service.

“If I call, they arrive in under 24 hours,” says Villard. Burlodge even keeps some essential parts stocked on site, just in case. “Being able to react quickly means that we can change the parts before the trolley fails. This ultimately reduces maintenance costs.”

“The trolley is the last link in the meal preparation chain. We must therefore choose the model with the utmost care,” says Mercier. “In a market with limited innovation, we have opted for avant-garde trolleys.” Burlodge agrees this is a healthy partnership.